Subscribe to Updates From TIDI Products

TIDI Customer Service: +1 800.521.1314

Email: excellence@tidiproducts.com

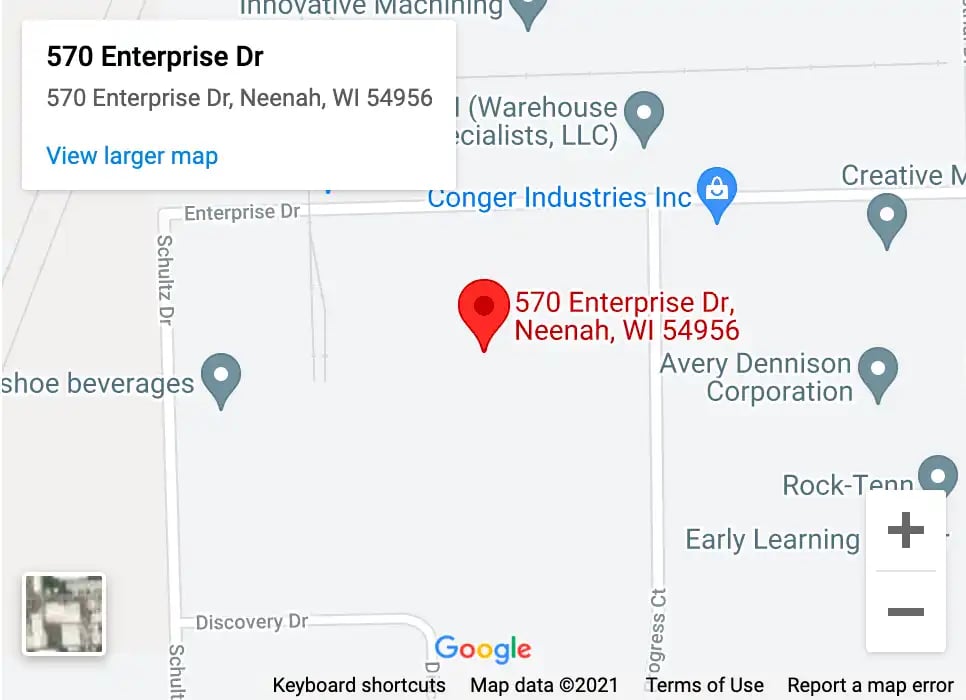

OUR LOCATION

570 Enterprise Drive

Neenah, WI 54956 USA

Phone: +1 920.751.4300

Toll-Free Fax: +1 800.837.7770

Fax: +1 920.751.4370

Subscribe to the TIDI Blog

TIDI Customer Service: +1 800.521.1314

Email: excellence@tidiproducts.com

OUR LOCATION

570 Enterprise Drive

Neenah, WI 54956 USA

Phone: +1 920.751.4300

Toll-Free Fax: +1 800.837.7770

Fax: +1 920.751.4370